All the press brake tools are unique in their capabilities and features. They offer a great number of benefits to the user by helping them get the most out of the machine and material. There are many different types of press brake machines on the market today. So, how do you know which machine is right for your specific application? The answer is simple – it depends on what you need to bend and how accurate your bends need to be.

In this blog post, we are going to discuss several benefits as well as advantages provided by precision press breaks. After reading, if you want to shop for press brakes, visit https://www.smbctools.com/. Let’s go!

1. Increased Efficiency

The biggest advantage provided by the precision press brakes is the increased efficiency. Compared to regular press brakes, which consume a significant amount of time to set up for the machine to execute each bend action, press brakes are faster. This happens because you must adjust the regular one each time you work on it, and you must ram the handle to bend it manually. On the other hand, precision press brakes come with automatic adjustments, so you just have to load the sheet of metal into the machine before hitting the start button. The remaining work will be efficiently and easily done by the machine. These qualities result in more efficient and easy parts production and will take reduced time.

2. Reduced Waste

Precision press brake tools can also help reduce waste. When parts are produced with inaccuracies, it often leads to scrap or rework. This wastes material and increases production costs. However, when parts are produced accurately with precision press brake tools, there is less waste and fewer production costs.

3. Greater Accuracy

Greater and improved accuracy is also one advantage offered by press brakes. When you’re bending sheet metal, even the slightest miscalculation can cause problems. With regular press breaks, it’s easy to make small mistakes that can ruin an entire batch of parts. However, with a precision press brake, you can be sure that your bends will be accurate every time. This is thanks to the fact that precision press brakes are fitted with special tools that help to guide the sheet metal into the correct position. As a result, you’ll save time and money by reducing scrap and rework.

4. Exceptionally Versatile

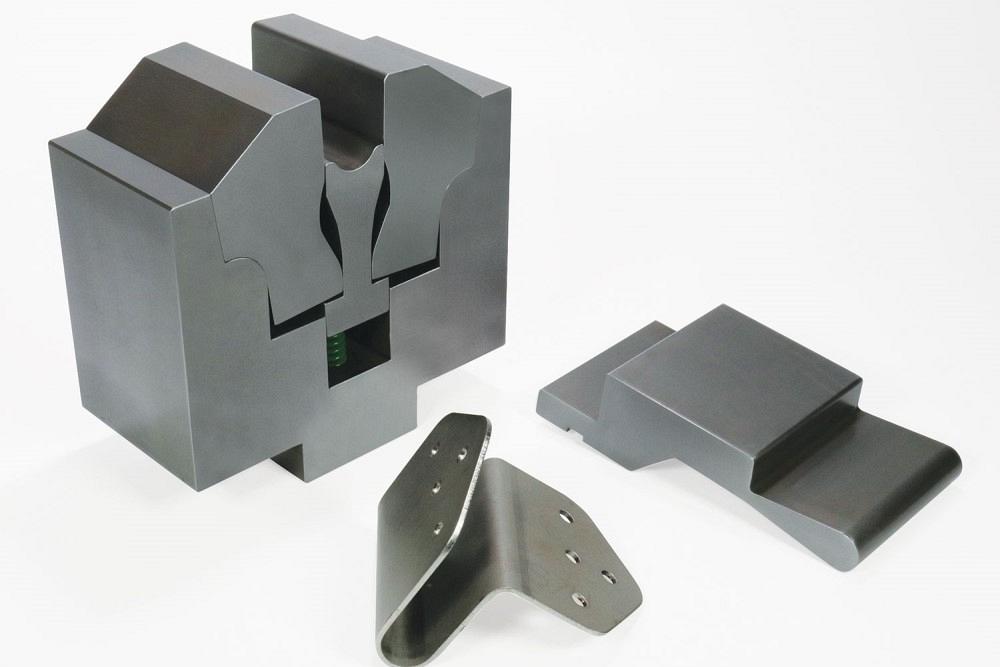

Lastly, precision press brakes are exceptionally versatile. Regular press brakes permit limited 90-degree or simple bending. The exact opposite case is with the press brake, which allows the production of much more complex shapes. This is because precision press brakes come with various tooling options. For example, you can get tooling that allows you to create V-shaped or U-shaped bends. You can even get tooling that allows you to create curves and circles. As a result, you’ll be able to produce parts that are significantly more complex than what you could produce with a regular press brake.

Conclusion

Above are some of the most important benefits of press brakes are given. If you require a machine that can produce precise, high-quality bends, then a precision press brake is exactly what you need. With a precision press brake, you’ll be able to produce parts that are more accurate and more complex than you could with a regular press brake – and you’ll be able to do it in less time too!